Introduction: The Spirit of the Blade

In the hands of a master, the katana is more than steel. It is history, spirit, and purpose forged into form. Each curve tells of discipline. Each edge speaks of patience. This is not just a sword; it is the echo of centuries, wielded with honor and crafted with care. The katana carries the mark of the samurai, even in silence. Its making is a sacred ritual—hammered, folded, polished—each step alive with profound meaning. Nothing is rushed, nothing wasted; every strike is measured, every detail considered. To understand the katana is to understand devotion. This is where the journey begins.

Forging Begins: Heat, Steel, and Focus

The katana’s story starts with steel—specifically, tamahagane—created from iron sand and smelted in a traditional tatara furnace. The smith selects only the purest pieces: bright, clean fragments meant for both a razor-sharp edge and a resilient spine. Forging commences as the smith heats the steel to a glowing state, folds it, and pounds it flat, repeating the process many times. Every fold refines the grain, removes impurities, and balances hardness with flexibility, so a hundred layers become one. Precision rules each step—the right temperature is crucial; too cool, and the metal may crack, too hot and it weakens. The smith’s eyes track color; ears heed the sound. With practiced hands, the forging becomes a dance of fire, hammer, and focus, imbuing the blade with its soul.

Shaping the Soul: Blade Formation

With heat, steel softens, ready for transformation. The smith measures every strike, working neither too quickly nor forcefully. Rhythm, not sheer power, guides the shaping. Here, the katana’s signature curve emerges—not simply for beauty, but for balance and precision, marking the blade as swift and fluid. Careful filing follows, allowing the blade to shed roughness, drawing out smooth, flowing lines that define its form. The blade’s curve is more than an aesthetic choice—it is movement and intention, allowing the sword to draw swiftly, cut cleanly, and return gracefully. In this moment, each contour reflects the essence of the sword’s future motion. Forged in fire, the katana is shaped into silent readiness.

Hardening and Tempering: Truth in Fire and Water

As the steel glows orange, it approaches its most delicate threshold. Swiftly, the blade is plunged into water; steam rises as it instantly hardens, gaining sharpness but also becoming brittle. Then comes tempering: the blade is gently reheated, allowing golden, bronze, and blue hues to ripple across its surface—each color a gauge of resilience being restored. The tempering process softens rigidity, lending the blade the ability to bend without breaking. Hardening and tempering are not adversaries, but partners; fire shapes, water seals, and heat returns to refine. Together, they create a blade capable of enduring both the demands of battle and the passage of time—sharp, strong, and trustworthy.

Polishing and Sharpening: Revealing the Path

Polishing marks the transition from creation to revelation. Using natural stones of increasing fineness, the polisher patiently removes the blade’s outer layers. Deliberate strokes encourage the steel to reveal its grain patterns—records of every fold and strike—while the hamon, or hardened edge line, emerges like a fingerprint, unique to each sword. The final polish brings clarity, not mere shine. Light flows down the blade, highlighting the subtle play of curves, bevels, and lines. In this process, nothing artificial is added—only the innate beauty and truth of the blade are brought to the surface.

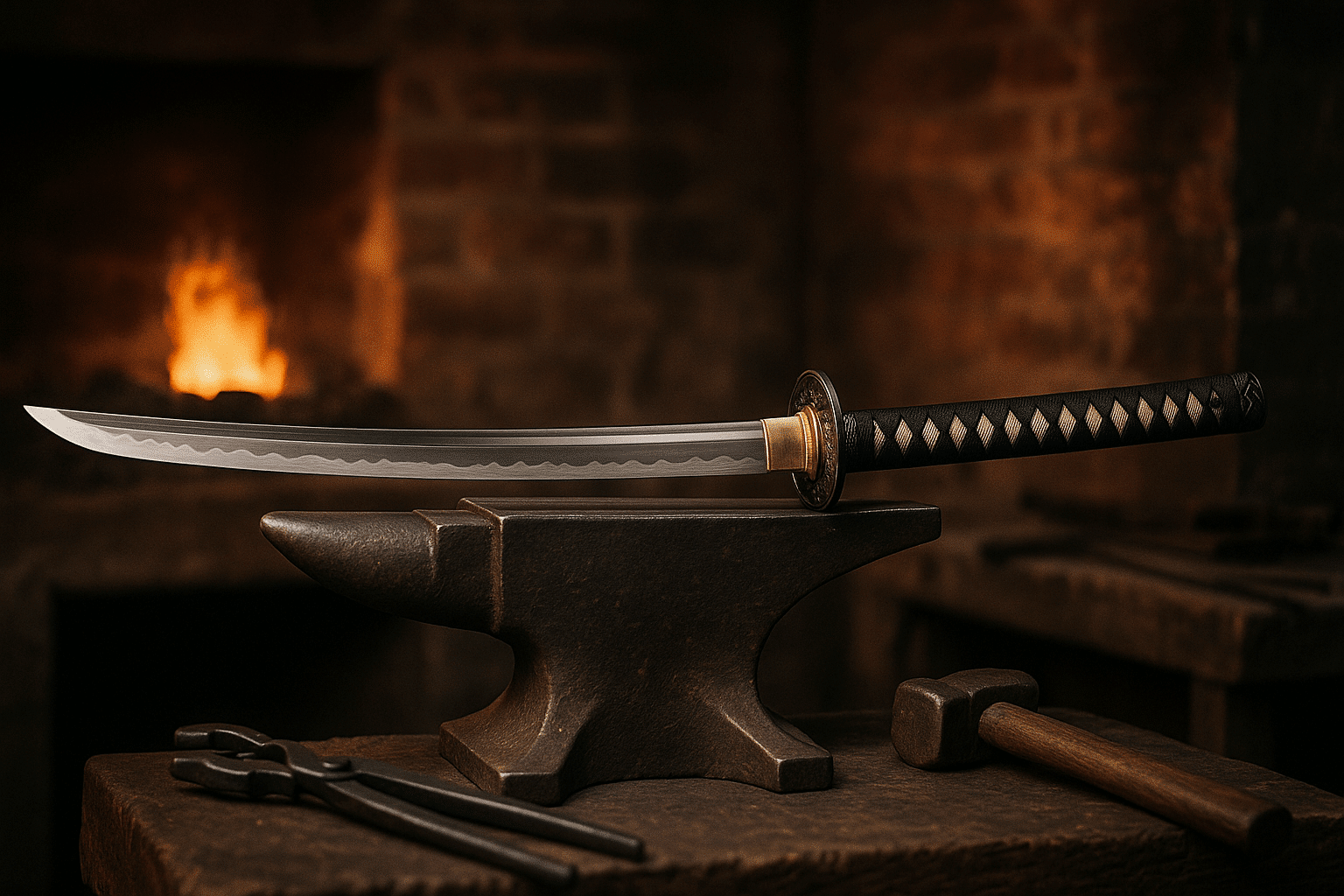

The Mounting: Crafting Balance and Harmony

Mounting the katana is a study of functional harmony. Each component—tsuba (guard), tsuka (handle), and saya (scabbard)—is fashioned with purpose. The tsuba, often simple and forged from iron, protects the hand and maintains the blade’s balance, never distracting from the whole. The tsuka is shaped precisely to fit, covered with ray skin and tightly wrapped for a secure, comfortable grip. Its crisscrossing cords both protect and showcase humble elegance. The saya, carved from lightweight wood and coated with lacquer, fits the blade like a second skin, ensuring safe, smooth draws and sheathing. Together, these elements extend the discipline and intent of the blade itself, transforming steel into a weapon that is balanced, functional, and true.

From Studio to Showroom: Finishing with Purpose

The final steps are performed in quiet concentration. Every katana is meticulously cleaned, its lines and surfaces scrutinized for flaws under steady light. The blade’s polish must not only catch the eye but reflect the care and technique invested in its making. Fittings are checked for seamless alignment and balance, the tsuka wrapping is tested, and the saya must cradle the sword with perfect tension—secure but effortless. Final details such as the cord’s color or a subtle lacquer finish are selected with restraint, honoring rather than overshadowing the steel. When at last the katana stands ready, it is not simply displayed but offered, its completeness a quiet testament to the craft, respect, and centuries of tradition behind its creation. It awaits its next purpose, finished not in haste, but with profound respect for all who were part of its journey.